A puristic homebrewer would make a neat printed circuit board by photo-etching method. Although it is effective for mass production like club kits, many homebrewers like me may think that it is too complicated for a single construction. A variety of dirty-but-easy construction methods are well known among homebrewers.

A puristic homebrewer would make a neat printed circuit board by photo-etching method. Although it is effective for mass production like club kits, many homebrewers like me may think that it is too complicated for a single construction. A variety of dirty-but-easy construction methods are well known among homebrewers.One cuts a printed circuit board stock into many small chips of sevral millimeters square. These chips are glued on another PCB stock. They are used as "lands" for hookup of components. Instead of these chips, several-megaohm resistors could be also used as stand-offs. Several-megaohm resistos are practically "insulators" in most applications.

The dead-bug construction method is also famous. One glues IC's and transistors upside down on a PCB stock with their pins pointing upwards. The pins could be bent by 90 degrees to point sidewards as well. Then resistors and capacitors are soldered on these pins.

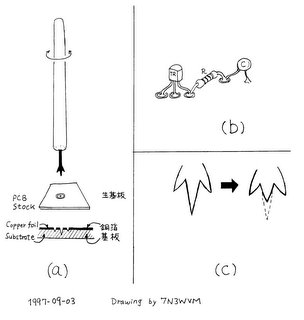

Following is yet another method, which I am trying successfully these days. In Japan, we have a hand-drilling tool called "nezumi-ba kiri" for woodworks like one shown in Fig.(a). I do not know whether similar one exists in other countries. This tool is originally used to drill a hole of several millimeters diameter in wood. If you drill a PCB with this tool and stop before you go through the board, you get a circular insulated "island" with a small hole at the center. This island is used for hookup of components as is shown in Fig.(b). It is better to shorten the center spearhead by a file as shown in Fig.(c) so that the center hole does not go through the board before annular trace is formed.

0 Komente:

Post a Comment

<< Fillim